Jack Alignment

This article provides guidance on how to move a jack back to a centered position if it is off-center and touching the cradle. It emphasizes the importance of not lubricating the cradle or side of the jack to reduce friction and avoid contact between the two. The article suggests bending the centerpin to move the jack back to a centered position, either by using a special metal anvil or by removing the whippen from the rail. The procedure involves positioning the whippen over a metal block and tapping the top of the jack with a hammer to move it towards the center. The article warns against hitting the jack too hard, which can cause a bent pin on both ends that needs replacement. Gradually increasing the force of the tap until the jack moves is recommended.

As I am rebuilding a grand action, I have noticed that several jacks are not returning smoothly, possibly due to scraping against the side of the opening in the repetition lever. Although lubricating with graphite has helped to some extent, a couple of jacks are still sluggish. Is it necessary to replace the entire whippen or is there a way to adjust the position of the jack?

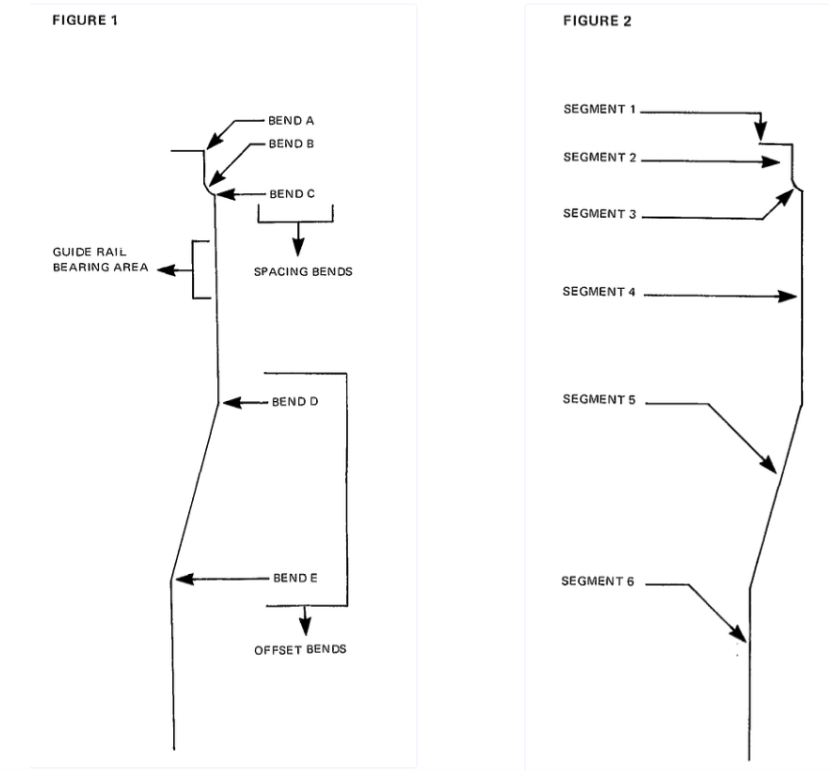

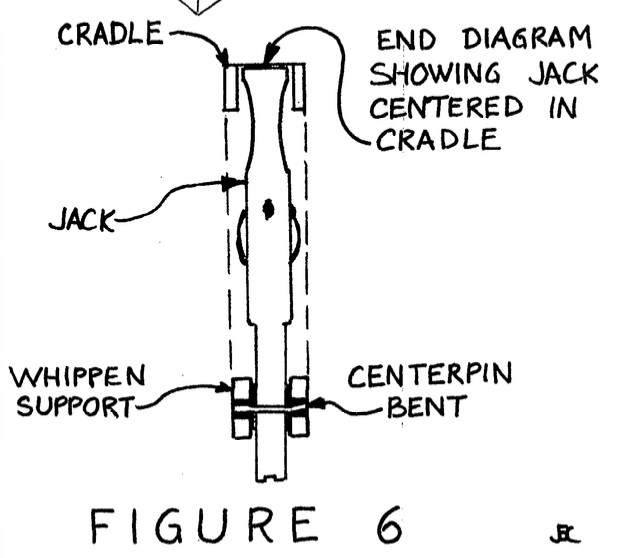

It is important to avoid lubricating either the cradle or the side of the jack to reduce friction between the two since they should not come into contact at all. If the jack is off-center and touching the cradle, the centerpin should be bent to move it back to a centered position. Some technicians use a special metal anvil to make this adjustment within the action, while others need to remove the whippen from the rail. However, the jack centerpin should not be removed as it needs to be bent while in place.

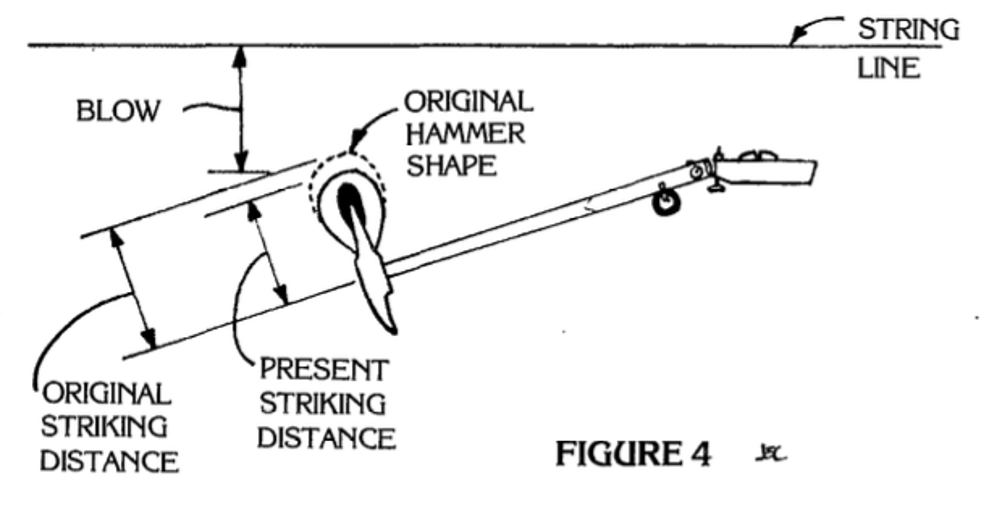

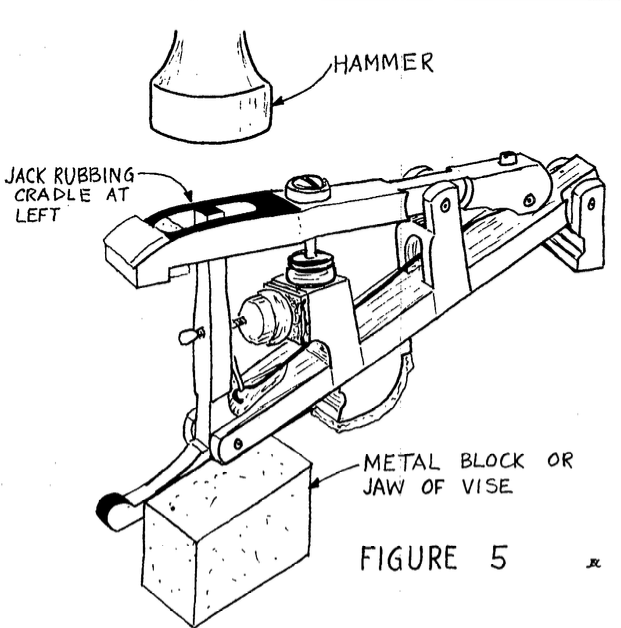

To move the jack, position the whippen over a metal block with the side of the whippen support that needs to be moved toward the jack resting on the block. Then, lightly tap the top of the jack with a hammer. If the jack is not centered, tap a little harder until it moves to the center. The centerpin will bend slightly to center the jack, which can be observed in Figure 6.

Although this method may seem crude, it is an accepted procedure that works because the pin will bend before the bushing is damaged, and the jack's range of movement is relatively short. However, it can be overdone, and hitting the jack too hard can cause it to rub against the opposite side of the cradle, resulting in a bent pin on both ends that needs to be replaced. Therefore, it is advisable to start with a light tap and gradually increase the force until the jack moves, developing a feel for the process and improving speed and accuracy over time.

What's Your Reaction?