The Importance of Precision in Manufacturing Piano Plates

The process of producing piano plates is an activity that requires great precision to ensure the acoustic neutrality of the finished product. The right mix of iron, steel, and chemicals is essential to the quality of the plate, which is melted in large furnaces and then polished, painted, and packaged for shipment to the piano manufacturer. All American piano plates are made from the same mixture in a single foundry in Ohio.

The manufacture of piano plates is a highly precise activity and is rightly referred to as the "milestone" of the casting industry. Most castings are subsequently machined, so tolerances are quite large. The piano plate must be a larger casting to allow for shrinkage to precise dimensions without machining. However, the main difference between normal iron castings (engine blocks, etc.) and piano plates is the requirement for acoustic neutrality. That is, a plate must be manufactured so as not to transmit or absorb energy from the strings. We have all seen plates with "bell-metal" inscriptions.

This is a high-level sales pitch because a plate with the chemical composition and acoustic properties of a bell would be completely unsuitable for use in a piano. The noise would be unbearable. Similarly, a plate made of energy-absorbing material is equally undesirable, which is why the aluminum plate never caught on. For cost reasons, the plate of the future may be made of welded steel, but the best plates have always been made of low-quality gray cast iron.

This material is relatively soft and has no resonant characteristics. The plates are cast from a controlled mixture of new iron, iron casting scrap, cold-rolled steel scrap, and chemicals. The right mix of these ingredients is critical to the acoustic neutrality of the finished product. Like a foreman in a large bakery calling for more yeast or sugar, the melter who mixes the materials for the iron plate must know exactly how much of each ingredient is needed. He sits in the cab of a crane near the foundry ceiling, alternately dipping a huge electromagnet into bins containing the separated ingredients. As the electromagnet picks up the iron or steel, an integrated scale weighs the material. If he has collected too much from one bin, the operator bangs the electromagnet against the side of the bin, causing some materials to fall.

If the scale shows an insufficient weight, the operator brings the magnet back down to take more material from the container. When the mix is correct, it is melted in the furnaces and poured into the molds. When the new plate is removed from the mold, the slag and sharp edges are polished, the holes for the tuning pins are drilled, and the pins are inserted. The plate is then bronzed and packed for shipment to the piano manufacturer, provided there are no obvious defects for the inspector. Defective plates are broken and recycled into the molten iron container, where they are fused together again with old engine blocks and other scrap castings. All American piano plates, from the cheapest vertical to the largest grand, are made from the same mixture in Springfield (Ohio) by one or the other of the country's two plate foundries.

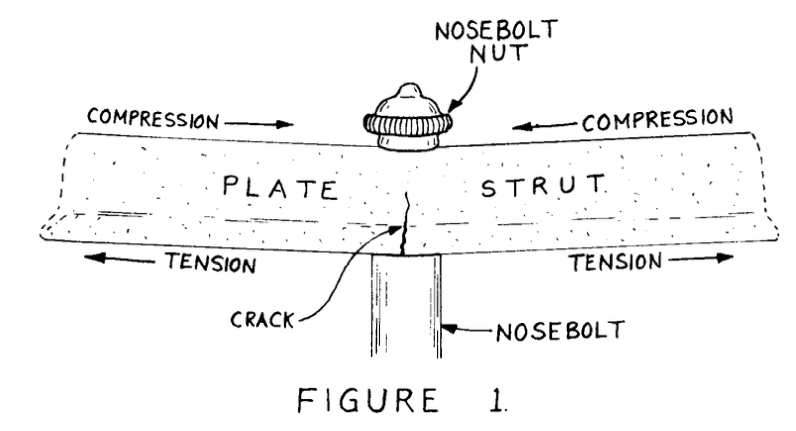

These round or decorative holes just behind the hitch pins on piano plates are sometimes referred to as "tonal holes," with the mistaken theory that they allow sound to escape from under the plate. In reality, there are two reasons for these holes, neither of which has anything to do with tone quality, volume, or appearance. The first reason these holes are necessary is that, as the molten iron shrinks as it cools, it must have an opening from which to shrink. The second reason for shrinkage holes has to do with uniform cooling. Thinner parts of a casting will cool faster than thicker parts, and if the disparity between the two is too great, an inherent

weakness will be built into the casting. To achieve maximum strength, the entire casting should cool at a relatively uniform rate. This means that solid areas of iron will actually be stronger with holes than without.

The only desirable acoustic function of the plate is to reflect sound. If one-third of the soundboard surface of a grand piano is covered by the plate, then one-sixth of the total case surface area is affected by the reflecting properties of the plate. Hypothetically, some vibrations are redirected to the soundboard from the underside of the plate. To maximize this effect, some technicians have filled and bronzed the underside of the plate before reinstalling it. The effectiveness of this procedure has not been conclusively established, which is not surprising considering the vast number of variables involved in tone quality, so the practice is not yet widespread.

There is no doubt that sound can be reflected, as evidenced by the simple phenomenon of echo, which is why people love to sing in the shower. Pianists have shown that a small variation in the length of a lid stick can make a big difference in sound projection, especially in a large room. When the lid is lowered, the tone is muffled; remove the lid and the tone spreads out, losing focus. This is easily demonstrated on any grand piano. Now, if someone were to find a way to remove, refinish, and replace a plate that is as easy as raising and lowering a piano lid, we would be in a better position to immediately evaluate some of the effects of plate reflection. Because it is so difficult to remove a cast iron plate, we do many things to the piano while the plate is out; and when we replace it, we do not know which change or changes caused the main difference in how the piano sounds. If I had to answer this question in one sentence, as many of you probably wanted to, I would have to say that the plate probably has a very small or no measurable acoustic effect on piano tone.

What's Your Reaction?