Some thoughts on the soundboard

This article discusses the condition of a soundboard in pianos and the factors that determine whether it needs to be replaced or can be reused. It also covers the importance of crown, how to measure it, and how a soundboard can be affected by humidity or water damage. The article also sheds light on the ignorance surrounding the diagnosis of cracks in pianos, which can be misleading at times. The article highlights the criteria for assessing the soundboard's condition, which includes its crown and whether or not the wood cells have been destroyed by being crushed. Finally, it explores the difference in the approach of an average technician and a specialist in dealing with a soundboard.

Our friend Walt Thatcher has more interesting thoughts to share with us, which I will intersperse with some comments of my own.

... Referring to a discussion: "Can a Soundboard be Recrowned?"

On the other hand, I recall that somebody at Baldwin took measurements and determined that a board requires little or no crown to perform well. I assumed that to mean that it is not necessary to measure the crown down to the last degree. Yes, any old board. Well, almost any old board. I believe Baldwin's position on this was that any measurable amount of crown at all is usually sufficient. But you must have some crown, or else the downpressure of the strings will cause the board to bow downward in a concave shape. This is what is known as negative crown. Pianos have been built with negative crown, but for this to work, the piano must have been designed that way. If an instrument were designed for positive crown, it will not perform well when bowed downward because the bridges won't be high enough in the middle to reach the strings. Lowering the plate significantly in such an instance will not work because the downbearing at the ends of the bridges would become excessive before adequate bearing could be achieved in the middle.

Now, back to Thatcher. Another issue I find concerning is the abysmal ignorance of so many people in our profession concerning cracks. Have you counted the number of customers who told you that a previous tuner claimed the soundboard was cracked and therefore ruined? Naturally, all of you learned people examined the board, and in nine out of ten cases replied, "Tut, tut, the board is fine." I recall 143 instances of this. Multiply that by 10,000, and Braid White must be exhausted from turning over in his grave.

I guess we've all heard that kind of statement. I have always assumed that in many cases, the customer was confusing the board with the block - a cracked block is indeed ruined. But I, too, have heard of tuners expressing alarm at a harmless hairline crack in the soundboard. That crack is often the least of the piano's problems.

Replacing soundboards as part of a reconstruction or overhaul program. Some time ago, I overhauled a 1890 Steinway. If I had completely replaced the soundboard, I would have risked losing that sweet quality of sound that it still maintains today. If artists complain about new wood, an owner would want to be absolutely certain about replacing the old quality wood. There must be a better way to determine its future life. First of all, a soundboard does not actually wear out in the sense that the glued boards can simply crack, creating gaps between one board list and another. Therefore, usually a strip of spruce wood is added to fill the gap left between the two boards, covering the crack that had formed. Many old instruments still have that quality of sound even though the soundboard is cracked.

First of all, I will say that a soundboard does not actually wear out in the same way as a pinblock. I routinely replace pinblocks whenever I have a plate out of a piano for whatever reason, but not soundboards. Many old instruments still have that singing quality Walt speaks about, and, as long as that board meets certain criteria, it can be shimmed and reused.

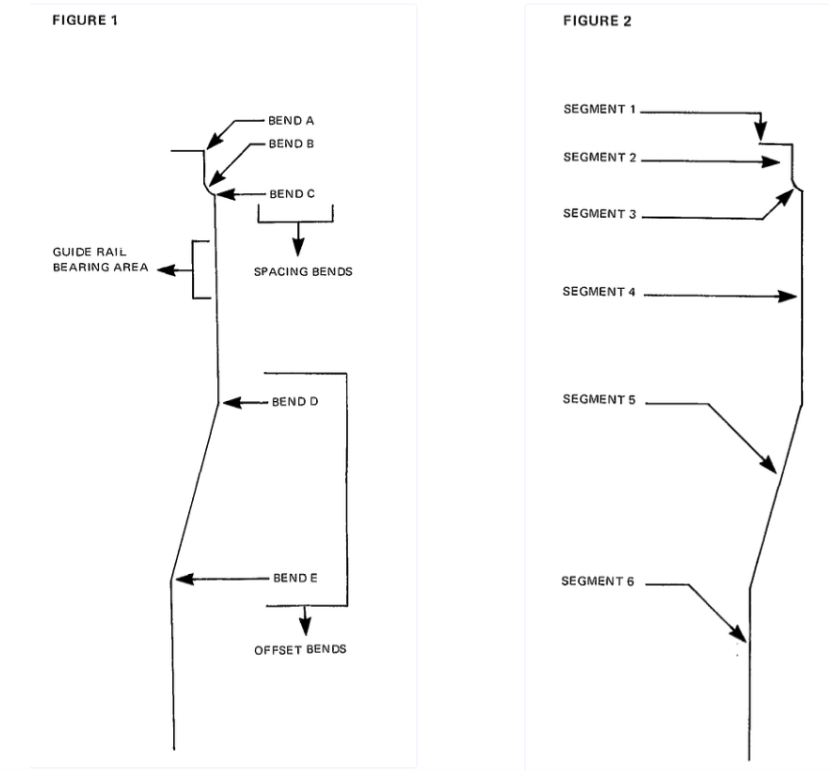

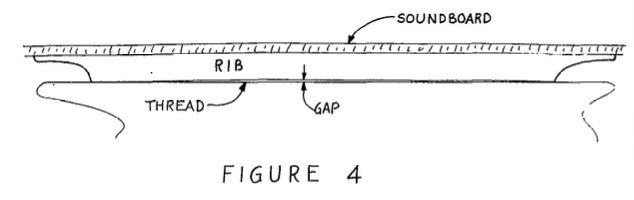

The first criterion is naturally crown, which can be measured by stretching a piece of thread along the bottom of the longest rib (see Figure 4). If there is a gap between the thread and rib in the middle, no matter how small, the board still has crown. Check the downbearing every three or four unisons throughout the scale to determine whether any one part of the board has caved downward. Then check the front-side downbearing in the high treble to be sure the bridge hasn't rolled and caused a twist in the board.

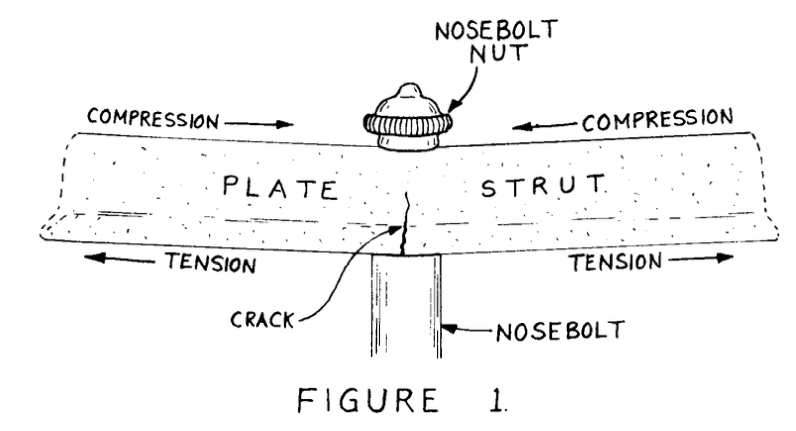

The second and final criterion would be whether or not wood cells have been destroyed by being crushed. In conditions of extreme humidity or water damage, a soundboard can belly up so far that it literally crushes itself against the downpressure of the strings, causing compression ridges. While the presence of such a defect is not necessarily fatal in itself (see page 12 of our March 1979 issue for a suggested repair procedure), if it is accompanied by numerous cracks and rib separations, the repair time may not be justified. This is a judgment call. The man who has the knowledge and facilities for soundboard replacement will quite logically reject a marginal board that would have been salvaged by the average technician.

The average technician is not so equipped and will quite understandably try to save every soundboard if he can. If the board cannot be saved, he knows he will have to send the piano to a larger shop, with the extra expense and waiting time.

What's Your Reaction?