Understanding Nosebolt Adjustment for Piano Maintenance

This article discusses the function of nosebolts and their role in downbearing in pianos. There is some disagreement among technicians about the designed function of nosebolts, with some suggesting that turning these bolts up or down can regulate downbearing. However, the author believes that nosebolts should not be considered dynamic regulators but rather static supporting members that stiffen the plate.

Occasionally, we hear technicians refer to nosebolts as "plate bearing screws." To me, this terminology suggests that the speaker may soon suggest that downbearing can or should be regulated by turning these bolts up or down. While there is some disagreement among technicians about the intended purpose of these bolts, I feel obliged to state the facts as I see them.

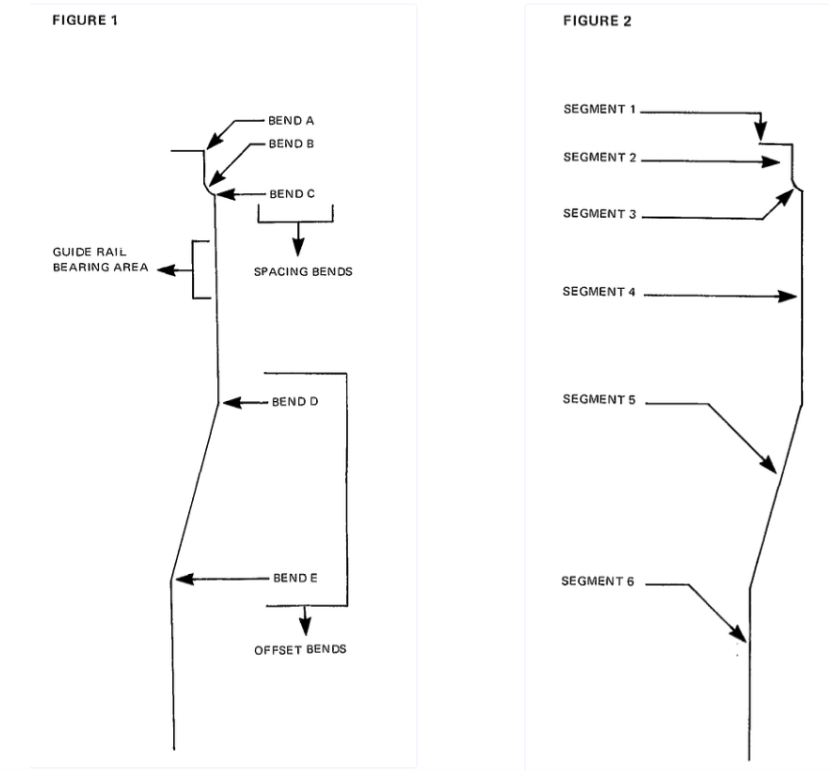

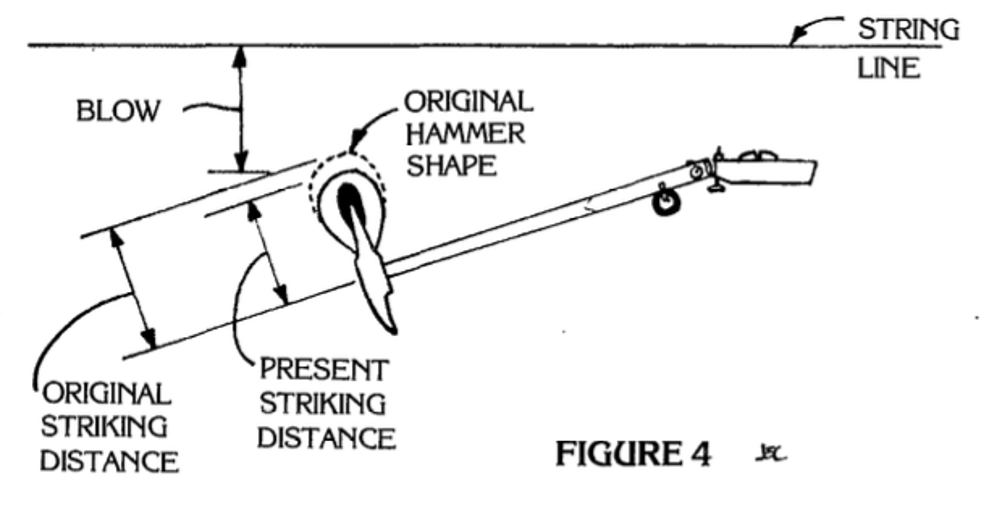

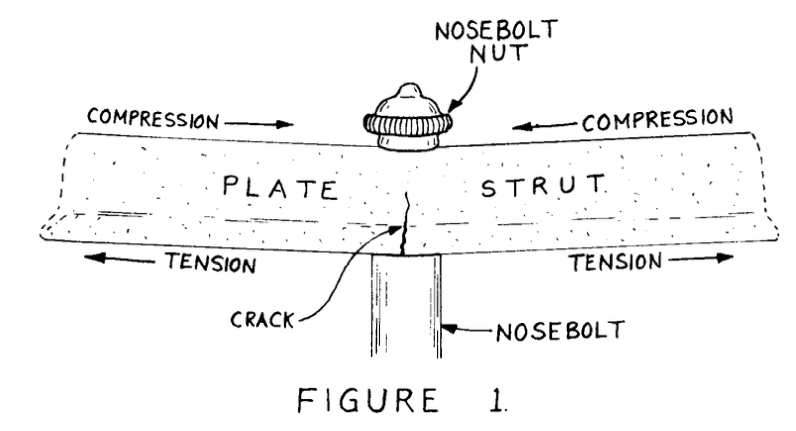

In my opinion, nosebolts should not be considered as dynamic regulators, but rather as static supporting members. Their purpose is to stiffen the plate, not to bend it. If the bearing needs to be altered, it should be done by changing the height of the entire plate, rather than forcing a distortion of one part of the plate. Cast iron is an excellent material for piano plates because of its strength under compression. However, when placed under tension, it is not very reliable. Figure 1 shows what happens to a plate strut when a nosebolt is turned down. As you can see, the upper portion of the strut is compressed, and the lower part is stretched. Because of the iron's weakness under tension, this strut is liable to crack at the bottom.

Some time ago, the Baldwin Company conducted several experiments to determine whether nosebolts were necessary. One experiment involved loosening a nosebolt nut on a grand piano when the strings were at pitch. They found that as the nut was unscrewed, the plate strut kept bending upward, following the nut. Had they removed the nut completely, the plate would undoubtedly have broken.

DOWNBEARING

Technicians often confuse the terms "crown" and "bearing," and sometimes use them interchangeably. In fact, a highly respected technician wrote that a technician could lower the plate in order to "raise the crown," which is not just questionable or subject to interpretation, but plainly incorrect.

Crown is simply the upward curvature or convexity of the soundboard. It exists whether or not the plate is even in the piano. The position of the plate has nothing to do with it.

Bearing describes the downward pressure of the strings on the bridge and soundboard. Since the string tension is a known factor, the amount of bearing can be measured by the angle of the string as it crosses the bridge.

The relationship between the two terms can be stated as follows: Bearing increases with crown, but crown does not increase with bearing. When the crown is increased, the bridge becomes higher in relation to the plate, thereby automatically increasing the string angle or bearing. Conversely, when the plate is lowered, the bearing naturally increases because the plate holds both ends of the string at a lower point. The bridge remains in the same position, so it is actually higher in relation to the plate, thereby increasing the string angle or bearing.

But what about the crown? It certainly cannot have increased. If anything, it flattens a bit more due to the added downpressure on the bridge. Therefore, it can be said without fear of contradiction that lowering the plate will always increase the downbearing, but will never increase the crown.

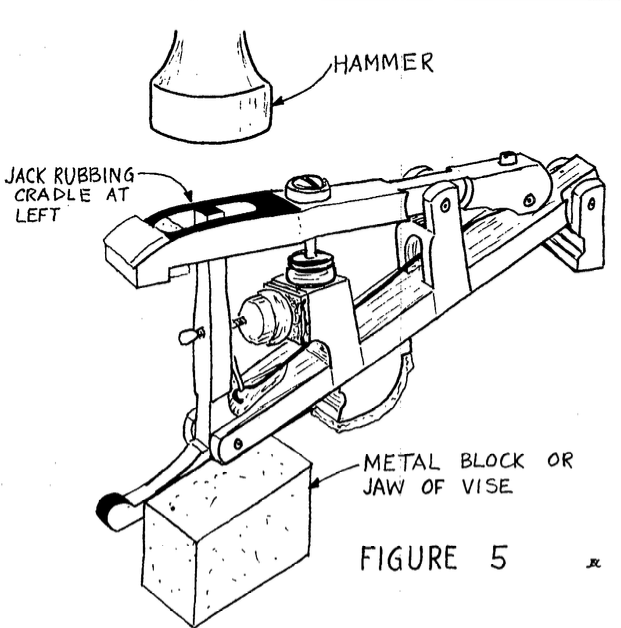

In discussing downbearing, it is important to differentiate between front and back bearing. Front bearing refers to the angle from the top of the bridge to the speaking length, while back bearing refers to the angle from the top of the bridge to the aliquot or waste end segment (refer to Figure 2). The total included angle of both front and back bearing angles is known as downbearing.

This distinction is essential because there are instances where one or both should be altered during piano rebuilding. High-quality piano manufacturers typically plane their bridges so that the speaking length side is slightly higher than the aliquot side for good reason. The bridge pin on the speaking length side is the end point of the scale, and the downbearing at that point must be sufficient to prevent the string from shifting in any direction. The same amount of bearing on the aliquot side would be excessive and hinder the board's diaphragmatic action. It is recommended to maintain about twice as much front bearing as back bearing throughout the scale.

To increase bearing on both sides of the bridge, lower the plate. To increase back bearing only, grind down the string rest; to increase front bearing only, lower the plate and shim up the string rest.

Lowering the plate involves evenly lowering all plate supports, including the pinblock. The tension must be entirely removed, and in nearly all cases, the plate must be removed from the piano. This job is strictly under the major rebuilding category and not something that can be done while performing routine maintenance or tuning in the customer's home.

What's Your Reaction?