Synthetic Materials for Piano Key Coverings

This article delves into the history of synthetic materials used for white piano key coverings, specifically as an alternative to ivory. The article first explores early synthetic materials, such as celluloid, milk protein, and phenolic resins, before examining Galalith, a synthetic ivory substitute that emerged around fifty years ago. The article goes on to discuss the production process for Galalith key coverings, as well as the benefits of using this material over alternatives such as celluloid. The article concludes by acknowledging the ongoing search for a suitable substitute for ivory, despite the success of Galalith and other synthetic materials.

While it may be just one of many components for a piano technician, the key covering is the direct connection between the player and the instrument. In some cases, it even garners media attention, such as when a grand piano is seized by customs due to a lack of proper documentation for importing ivory. Additionally, there have been numerous inquiries about how to best disinfect keys, with technicians often being asked to suggest whether alcohol or soap is better, even though they may not know the name of the white material used. As such, this article focuses on white key coverings, specifically synthetic materials that have been used as an alternative to ivory for over a century.

Early Synthetic Materials for Key Coverings

The first keys with plastic coverings are now considered antiques. Reports on the scarcity and rising cost of ivory, as well as experiments with synthetic alternatives, were already featured in the Zeitschrift für Instrumentenbau (Magazine for Instrument Making) in the 1880s. Some of the suggested mixtures sound like they came from a witch's kitchen, such as a mixture of fish glue, brandy, and finely powdered eggshells. However, some of the ingredients listed are still relevant to ivory substitutes today, such as cellulose, gelatine, mineral materials, and phosphoric acid.

Celluloid was the first synthetic material to be considered, discovered around 1870. When cellulose is treated with nitrating acid (a mixture of nitric and sulfuric acid), cellulose nitrate is produced. The degree of nitration varies depending on the acid concentration and reaction time, with gun cotton, used in explosives, being the most extreme case. To produce celluloid, less concentrated nitrating cellulose is treated with camphor. The resulting product is thermoplastic, meaning it can be molded when heated and is soluble in organic solvents like acetone. Celluloid can be used to create a range of objects and semi-finished products.

Celluloid is a colorless synthetic material that can be easily dyed. While not as explosive as gun cotton, it is still highly flammable, leading to its replacement as a carrier material for photographic film. However, it has been used in the production of table tennis balls up until recent times.

At the turn of the 20th century, another natural material that had been chemically modified began to be used alongside cellulose: milk protein. Hardened with formaldehyde and processed under pressure, it can be molded into a plastic mass. Additionally, phenolic resins, including the well-known Bakelite, were available from the beginning of the 20th century. However, these tend to darken and are mostly dyed dark brown or black, making them unsuitable for white key coverings.

A comprehensive description of synthetic key coverings up until the mid-20th century can be found in Josef Göbel's book "Grundzüge des modernen Klavierbaues" (Basics of Modern Piano Building), published in Leipzig in 1952. According to the book, in Germany in 1913, 105,000 pianos out of a total production of 170,000 had ivory keys, accounting for around 75%. The remaining 35,000 instruments had plastic key coverings, which cost around 10% of ivory. The percentage of ivory keys has decreased considerably since then. In 1929, only 35% of the 35,600 pianos produced had ivory keys, and the numbers have likely continued to fall in recent years. This shift away from ivory cannot be attributed solely to its increasing cost, as the cost of an ivory keyboard for a piano priced at 1500 Deutschmarks was around 5% of the total cost, compared to 0.5% for synthetic materials. This trend away from ivory was observed not only in Germany but also in other major centers of piano manufacturing, such as the USA, England, and France. Nonetheless, it is estimated that around a quarter of all acquired ivory has been used by the piano industry, with another quarter being processed into billiard balls and the remaining half being employed in arts and crafts, such as carving.

Throughout the history of piano making, there has been a constant search for a substitute for costly ivory. The emergence of celluloid was seen as the solution, and it quickly dominated the market for key coverings. However, this material, although similar to horn with its specific light mass, was not entirely welcomed by manufacturers due to its flammability and tendency to yellow with age. Nonetheless, it initially had a remarkable similarity to ivory.

Around fifty years ago, various industries discovered an alternative material with similar properties to ivory made from casein. During attempts to produce a washable white panel, treating casein with formaldehyde led to the creation of a plastic compound strong enough to be processed into a range of products. This new material was called "Galalith," from the Greek words "gala" and "lithos," meaning "milk stone."

At first, there were considerable difficulties in producing Galalith with the appropriate dimensions and color for the trade. Eventually, a synthetic ivory substitute was achieved, and Galalith displayed an attractive shade of white that was resistant to light, unlike ivory. Because it is produced under enormous pressure, Galalith will not prematurely "hollow out," and the material has no pores, unlike celluloid. It is also odorless and nonflammable.

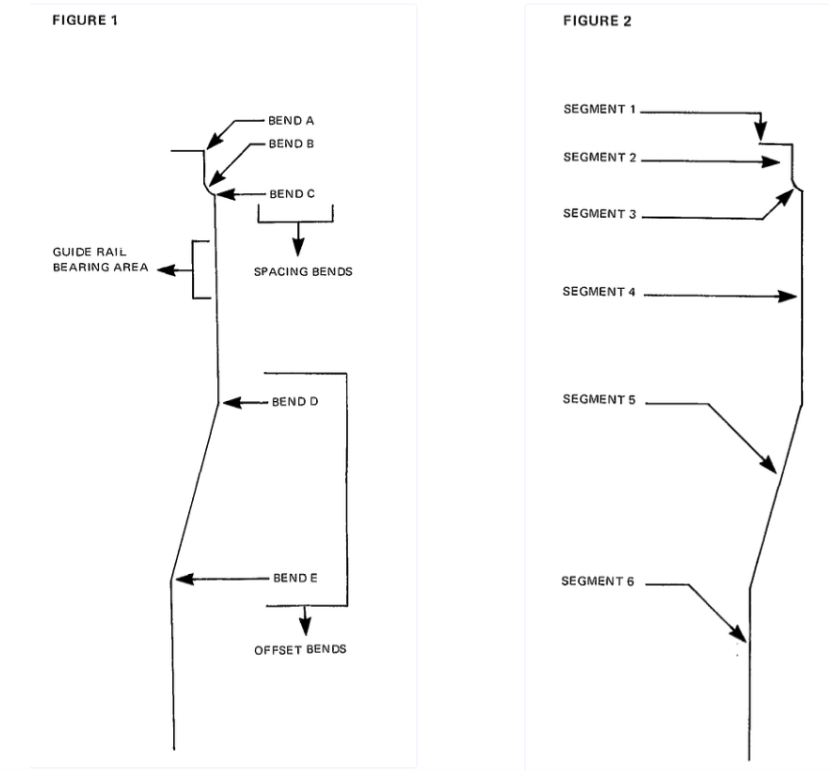

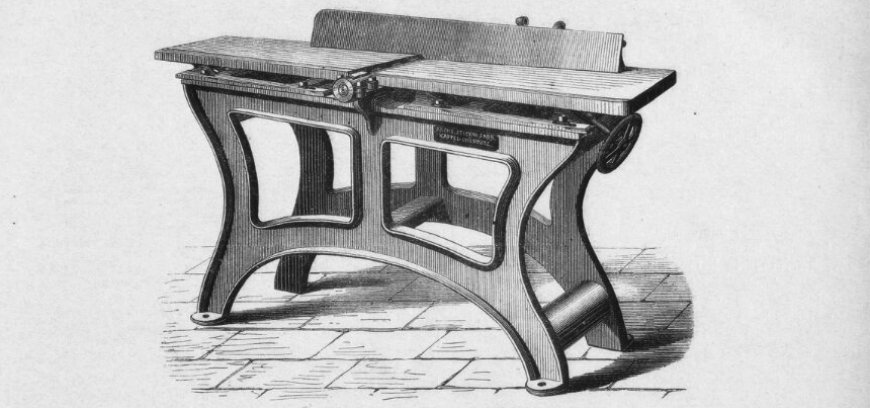

Raw Galalith plates are processed by sanding down to the appropriate thickness for key covering size, sanding from both sides to avoid tension in the material that might lead to warpage. Then, the plates are sanded on a polishing disc with pumice and water, being careful not to produce grooves. The plates are cut to size with a sharp, finely-toothed circular saw and glued to the key base with leather glue under pressure until the glue is dry. The side edges are evenly sanded or filed, and the entire keyboard is clamped to a board and fine-sanded with chalk and white spirit before being buffed to a deep shine with a little soft soap and Vienna polishing chalk.

Galalith is a synthetic material created by treating casein with acids or salts to form an insoluble mass, which is then dehydrated under pressure before being immersed in formaldehyde to produce a hard, translucent material. Galalith can be dyed and compounded with other substances, such as soil, cork powder, wood, or glycerine. An improved synthetic ivory, known as "Elfenit," has recently become available, which is also made from Galalith. A similar key covering from England, known as "Tuskite," has also been successfully employed. As the scarcity of ivory continues, more and more synthetic alternatives are likely to be produced.

Until the 1960s, many upright and grand keyboards received white coverings made from celluloid or Galalith. Almost all cheap harmoniums were thus fitted. Celluloid was also common as a key front material, often even for ivory keys. In America, the brand name "Pyralin," a cellulose product made by the Dupont Co., was synonymous with plastic key coverings. The name presumably comes from the original term for cellulose nitrate - "Pyroxylin."

Although these products were intended to imitate natural ivory, it is easy to distinguish the real thing. However, it is not so easy to recognize whether a product is made from celluloid or Galalith, and with these brand names listed, the basic material can mostly only be guessed at through the invented word. Sometimes, the advertising points to the non-flammability of the material, which indicates celluloid.

The substances can usually be identified by different treatments: celluloid smells of camphor when sanded or sawed and burns quickly with considerable soot emission. Galalith, on the other hand, chars and smells like burnt protein. Celluloid dissolves in acetone, nitro thinner, and other organic solvents but is relatively water-resistant. This contrasts with Galalith, which is not affected by solvents but is sensitive to moisture.

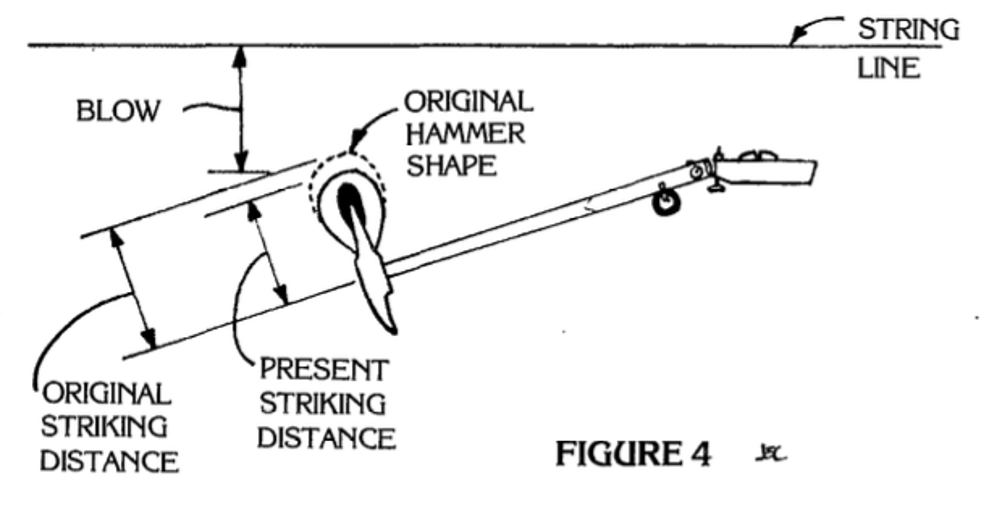

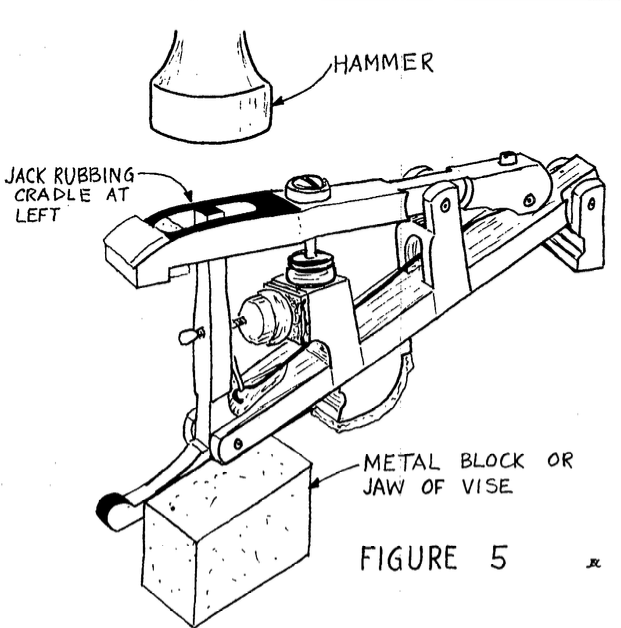

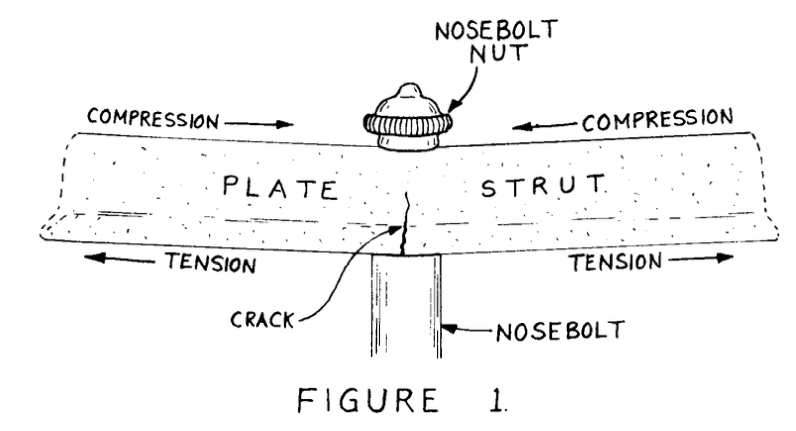

In the passage quoted by Josef Göbel, Galalith is presented as the more valuable material compared to celluloid. In old price lists, Galalith is mostly twice as expensive as celluloid. Yet after many decades, one often finds that celluloid has aged better than Galalith. There are many keyboards with celluloid coverings that are in top condition, even after 100 years. This can be true for Galalith, but often problems occur. At worst, it becomes brown, especially in the middle section where the keys are excessively played. Also, tension can ensue in the glue joint because of shrinkage in the Galalith, leading to lateral splits in the key, or the Galalith holds up but bulges upwards, coming apart with the glue and a thin layer of spruce along the length of the key.

Acrylic Glass for Key Coverings

In the mid-20th century, a new synthetic material called acrylic glass, made from poly-methylmethacrylate (PMMA), began to dominate the market as a key covering material. Although it had been available since the 1930s and was already used in musical instrument making, it was not initially considered suitable for key coverings. It was mainly used in airplane or automobile domed windows and musical instruments such as harpsichord jacks, wind and string instruments, and even a grand piano with a plexiglass case.

Acrylic glass was initially introduced almost unnoticed as a material for key coverings, but soon became the leading material in the 1960s. The material is thermoplastic, which means it can be produced in panels or blocks and can be machine processed or made into granules for injection molding, extrusion, and other forming processes. Like celluloid and Galalith, it can be processed in sheets for making key coverings. However, injection molding made it possible to produce single key coverings with fronts in one piece.

Acrylic glass quickly became the preferred material for key coverings because of its durability and material properties. It can be dyed and ages well, and is resistant to water, acids, medium-strong alkaline solutions, petrol, and oil. However, ethanol, acetone, and benzene can attack its surface. It should not be cleaned with alcohol or solvents, as stress corrosion cracking can occur. It is combustible and burns with a yellow flame.

In conclusion, while previous plastic materials were based on chemically altered natural products, acrylic glass was entirely synthetic, and it surpassed its predecessors as a suitable and preferred material for piano key coverings. Its durability, flexibility, and resistance to a range of substances made it an excellent choice for the job.

New Key Covering Products

In the piano manufacturing industry, finding a substitute for costly ivory has been a continuous quest. While synthetic materials such as celluloid, galalith, and acrylic glass have been used for many years, some pianists find the inability of acrylic glass to absorb water a disadvantage. This feature makes it resistant to dirt and easy to clean but can make fingers slip on the surface, leading to an insecure feeling when playing. Consequently, alternative materials have been tested, including mammoth ivory and bone, but these are only suitable for a small number of customers.

Fortunately, several manufacturers offer synthetic materials that are appropriate for key coverings. These new products are typically synthetic resins that have been modified by adding mineral substances. Manufacturers have drawn on the experience of other industrial branches that use panel materials, such as those used in interior construction.

Recently, new products have been announced under the description of "synthetic ivory." There seems to be a certain demand for these products as producers of decorative objects, artistic crafts, and ivory carvers are interested in such alternatives. The piano trade might benefit to a certain extent from this trend, although it must be acknowledged that experience with acrylic coverings has been very good for over 50 years. It cannot be said that there is widespread dissatisfaction with acrylic among piano players, whether they are beginners, adepts, or professionals.

What's Your Reaction?